Tour à bois CNC à alimentation auxiliaire pour pieds de meubles

$7500-$9800

- Modèle : CT-1530

- Dimensions utiles : diamètre 120-300 mm, longueur 1500 mm

- Catégorie : Tour à bois CNC à trois axes

- Conseils techniques continus pour les clients finaux et les concessionnaires

- Modes de paiement flexibles – Paiements sécurisés en ligne et hors ligne – PayPal, Alibaba, T/T, cartes acceptées

- Réseau de transport international garantissant une livraison à temps partout

- Garantie complète d'un an pour l'unité complète avec des plans de protection supplémentaires pour les pièces principales

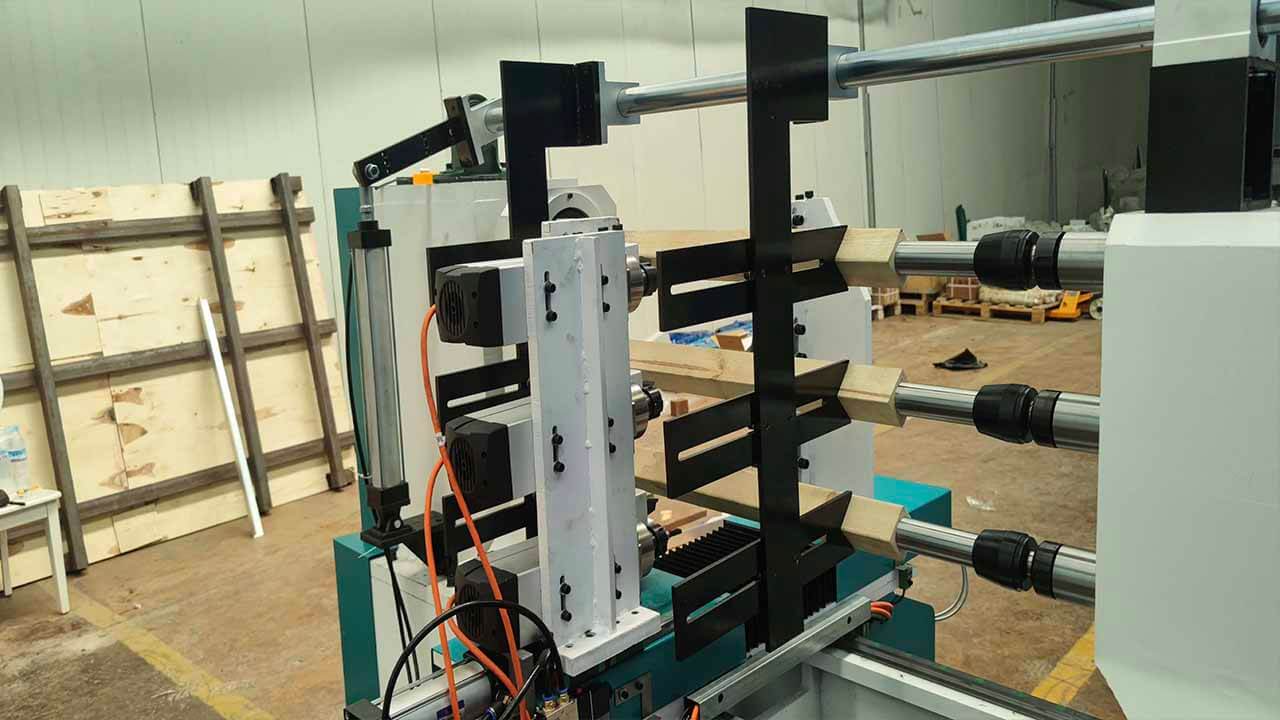

Présentation du produit : Tour à bois CNC à alimentation auxiliaire pour pieds de meubles

Le Tour à bois CNC à alimentation auxiliaire pour pieds de meubles Cette machine de haute précision et à haut rendement est conçue pour le tournage et le façonnage automatiques de pièces cylindriques en bois, telles que des pieds de meubles, des balustres d'escalier, des colonnes de table et des montants de lit. Sa structure robuste en fonte et son système de commande DSP avancé lui confèrent stabilité, facilité d'utilisation et fiabilité. La conception à alimentation auxiliaire permet un usinage en continu, réduisant ainsi le travail manuel et augmentant la productivité. Rails de guidage linéaires Hiwin de Taïwan, Transmission à vis à billes TBIet un broche de conversion de fréquenceLa machine assure une rotation fluide, une coupe précise et une excellente finition de surface. Compatible avec ArtCAM, Type 3, Ucancamet d'autres logiciels de conception, il prend en charge le transfert de fichiers USB pour un traitement flexible et efficace. Ce tour à bois CNC est idéal pour fabricants de meubles, usines de travail du bois et ateliers d'artisanat décoratif à la recherche de précision, d'automatisation et de durabilité à long terme.

Caractéristiques principales du tour à bois CNC à alimentation auxiliaire pour pieds de meubles

- Système de contrôle DSP avancé : Doté d'une télécommande DSP conviviale, rendant son utilisation simple, efficace et facile à apprendre, il est idéal pour les débutants comme pour les professionnels du tournage sur bois CNC.

- Cadre en acier renforcé : Construite avec une base en acier soudé épais de 2,9 mètres de long, elle assure une stabilité exceptionnelle, des vibrations minimales et une durabilité à long terme lors de l'usinage à grande vitesse.

- Contrôle de vitesse variable : Il est doté d'un système de réglage de la vitesse par fréquence basé sur un variateur de fréquence qui permet un contrôle flexible de la vitesse de la broche, évitant ainsi les vibrations du bois et assurant un tournage en douceur.

- Composants de mouvement de précision : Utilise Rails de guidage carrés linéaires Hiwin de Taïwan, crémaillère hélicoïdale et transmission à vis à billes TBI pour une haute précision, un fonctionnement stable et une durée de vie prolongée.

- Entraînement puissant par moteur pas à pas : Équipé de moteurs pas à pas à couple élevé et de pilotes Yako 2811 pour assurer un contrôle de mouvement fiable et un traitement précis pour les conceptions complexes en bois.

- Capacité de double coupe : Compatible avec les outils d'ébauche et de finition pour une meilleure qualité de surface, un temps de cycle réduit et une efficacité de production accrue dans le travail du bois en série.

- Dispositif de fixation du point central : Dotée d'un système de positionnement central qui maintient fermement la pièce à usiner, elle augmente la précision d'usinage et assure une symétrie parfaite lors du tournage.

- Compatibilité logicielle : Entièrement compatible avec les logiciels de conception et de gravure populaires tels que ArtCAM, Type3, Ucancam et JDpaint, permettant un transfert de fichiers facile et une personnalisation des motifs via une interface USB.

Spécifications du tour à bois CNC à alimentation auxiliaire pour pieds de meubles

| Article | Détails |

|---|---|

| Châssis de machine | Structure en fonte haute résistance pour une stabilité et une résistance aux vibrations optimales |

| Diamètre de braquage maximal | 120–300 mm (options personnalisées disponibles jusqu'à 400 mm) |

| Longueur de braquage maximale | 1500 mm (modèle étendu en option jusqu'à 2000 mm) |

| Vitesse de broche | Broche rotative haute vitesse réglable de 0 à 3000 tr/min |

| Système d'entraînement | Moteurs pas à pas modèles 450C/450B associés à des contrôleurs Yako 2811 pour une commande précise |

| Rail de guidage | Glissières carrées linéaires HIWIN de 25 mm (Taïwan) pour un mouvement fluide et précis |

| Méthode de transmission | Crémaillère et pignon avec vis à billes de précision TBI (Taiwan) pour une alimentation stable |

| Pression d'air de service | 0,6–0,8 MPa |

| Contrôleur CNC | Système de contrôle DSP avancé pour des performances fiables |

| Logiciels compatibles | Compatible avec Type3, ArtCAM, Artcut, Ucancam, JDpaint et autres logiciels de conception |

| Langage de programmation | Format de code G standard |

| Connexion informatique | Interface de données USB pour un transfert de fichiers rapide et facile |

| Tension de fonctionnement | 380 V CA, 50/60 Hz |

| Système de lubrification | Lubrification centralisée à l'huile pour un entretien facile et une longue durée de vie |

| Environnement de travail | Température : 0–45 °C ; Humidité : 30–75 % HR |

| Dimensions de la machine | 2000 × 1300 × 1350 mm |

| Poids net | Conception robuste de 1600 kg pour un usinage stable |

Applications de l'alimentation auxiliaire sur un tour à bois CNC pour pieds de meubles

Le tour à bois CNC avec avance auxiliaire est largement utilisé pour l'usinage de diverses pièces. produits cylindriques et artistiques en bois tel que bols, tubes et objets décoratifsIl est idéal pour produire balustres d'escalier, poteaux de départ, colonnes d'escalier, pieds de table, pieds de chaise, pieds de canapé et pieds de tabouret de bar avec une précision constante. La machine est également parfaite pour tourner Colonnes romaines, lavabos, vases en bois, montants de lit, traverses de chaises, rampes, pieds boule, lampadaires et battes de baseballConvient pour fabrication de meubles, décoration intérieure et production artisanale du bois, ce tour à bois CNC offre une finition de haute qualité pour composants en bois incurvés, coniques, sphériques et cylindriques Fabriqué à partir de matériaux comme le chêne, le frêne, le bouleau, le teck et le palissandre.

Présentation du produit : Tour à bois CNC à alimentation auxiliaire pour pieds de meubles

Prêt à améliorer votre tournage sur bois ?

Obtenez votre personnalisation Solution de tour à bois CNC aujourd'hui. Contactez-nous pour un devis détaillé et une consultation technique