Auxiliary feeding CNC Wood Turning Lathe for Furniture Legs

$7500-$9800

- Model: CT-1530

- Working Size: Dia 120-300mm, Length 1500mm

- Category: Three Axis CNC Wood Lathe

- Ongoing Technical Guidance for Both End-Clients and Dealers

- Flexible Payment Methods – Secure Payments Online & Offline – PayPal, Alibaba, T/T, Cards Accepted

- International Transport Network Ensuring On-Time Delivery Anywhere

- Comprehensive One-Year Warranty for Complete Unit with Additional Protection Plans for Major Parts

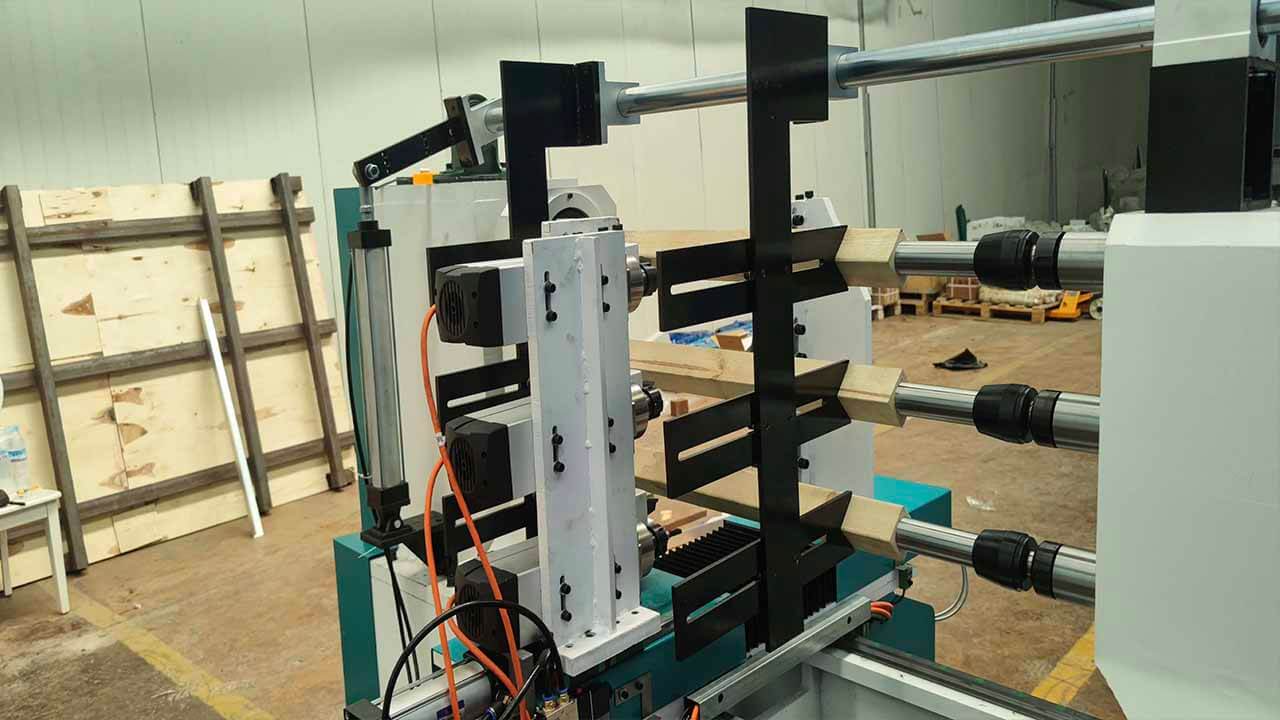

Product Overview of Auxiliary feeding CNC Wood Turning Lathe for Furniture Legs

The Auxiliary Feeding CNC Wood Turning Lathe for Furniture Legs is a high-precision and high-efficiency machine designed for automatic wood turning and shaping of cylindrical workpieces such as furniture legs, stair balusters, table columns, and bed posts. Built with a heavy-duty cast-iron structure and an advanced DSP control system, it ensures stability, easy operation, and reliable performance. The auxiliary feeding design allows continuous machining, reducing manual labor and boosting productivity. Equipped with Taiwan Hiwin linear guide rails, TBI ball screw transmission, and a frequency conversion spindle, the machine provides smooth rotation, accurate cutting, and excellent surface finish. Compatible with ArtCAM, Type3, Ucancam, and other design software, it supports USB file transfer for flexible and efficient processing. This CNC wood lathe is ideal for furniture manufacturers, woodworking factories, and decorative craft workshops seeking precision, automation, and long-term durability.

Key Features of Auxiliary feeding CNC Wood Turning Lathe for Furniture Legs

- Advanced DSP Control System: Equipped with a user-friendly DSP handheld controller, making operation simple, efficient, and easy to learn — ideal for beginners and professionals in CNC wood turning.

- Reinforced Steel Frame: Built with a thick welded steel base measuring 2.9 meters in length, ensuring outstanding stability, minimal vibration, and long-term durability during high-speed machining.

- Variable Speed Control: Features an inverter-based frequency speed adjustment system that allows flexible spindle speed control, preventing wood flutter and ensuring smooth turning performance.

- Precision Motion Components: Utilizes Taiwan Hiwin linear square guide rails, helical rack, and TBI ball screw transmission for high precision, steady operation, and extended service life.

- Powerful Stepper Motor Drive: Fitted with high-torque stepper motors and Yako 2811 drivers to deliver reliable motion control and accurate processing for complex wood designs.

- Dual Cutting Capability: Supports both roughing and finishing tools for improved surface quality, reduced cycle time, and enhanced production efficiency in mass woodworking.

- Central Point Fix Device: Equipped with a central positioning system that firmly holds the workpiece, increasing machining accuracy and ensuring perfect symmetry during turning.

- Software Compatibility: Fully compatible with popular design and engraving software like ArtCAM, Type3, Ucancam, and JDpaint, allowing easy file transfer and pattern customization via USB interface.

Specification of Auxiliary feeding CNC Wood Turning Lathe for Furniture Legs

| Item | Details |

|---|---|

| Machine Frame | High-strength cast iron structure for stability and vibration resistance |

| Maximum Turning Diameter | 120–300mm (custom options available up to 400mm) |

| Maximum Turning Length | 1500mm (optional extended model up to 2000mm) |

| Spindle Speed | Adjustable 0–3000 rpm high-speed rotary spindle |

| Drive System | Stepper motors model 450C/450B paired with Yako 2811 drivers for precision control |

| Guide Rail | 25mm Taiwan HIWIN linear square guideways for smooth and accurate motion |

| Transmission Method | Rack and pinion with Taiwan TBI precision ball screw for stable feed performance |

| Working Air Pressure | 0.6–0.8 Mpa |

| CNC Controller | Advanced DSP control system for reliable performance |

| Compatible Software | Supports Type3, ArtCAM, Artcut, Ucancam, JDpaint, and other design software |

| Programming Language | Standard G-code format |

| Computer Connection | USB data interface for quick and easy file transfer |

| Operating Voltage | AC 380V, 50/60Hz |

| Lubrication System | Centralized oil lubrication for easy maintenance and long service life |

| Working Environment | Temperature: 0–45°C; Humidity: 30–75% RH |

| Machine Dimensions | 2000 × 1300 × 1350 mm |

| Net Weight | 1600 kg heavy-duty design for stable machining |

Applications of Auxiliary feeding CNC Wood Turning Lathe for Furniture Legs

The CNC Wood Turning Lathe with auxiliary feeding is widely used for machining various cylindrical and artistic wooden products such as bowls, tubes, and decorative crafts. It is ideal for producing staircase balusters, newel posts, stair columns, table legs, chair legs, sofa legs, and bar stool legs with consistent precision. The machine is also perfect for turning Roman pillars, washstands, wooden vases, bed posts, chair stretchers, handrails, bun feet, lamp stands, and baseball bats. Suitable for furniture manufacturing, interior decoration, and wood craft production, this CNC wood lathe delivers high-quality finishing for curved, conical, spherical, and cylindrical wood components made from materials like oak, ash, birch, teak, and rosewood.

Product Showcase of Auxiliary feeding CNC Wood Turning Lathe for Furniture Legs

Ready to Upgrade Your Wood Turning?

Get your customized CNC wood lathe solution today. Contact us for detailed pricing and technical consultation