CT-1512 3 Axis Automatic Wood Turning Cnc Wood Lathe Machine

$7500-$10800

- Model: CT-1512-S

- Working Size: Dia 120-300mm, Length 1500mm

- Category: Three Axis CNC Wood Lathe

- Ongoing Technical Guidance for Both End-Clients and Dealers

- Flexible Payment Methods – Secure Payments Online & Offline – PayPal, Alibaba, T/T, Cards Accepted

- International Transport Network Ensuring On-Time Delivery Anywhere

- Comprehensive One-Year Warranty for Complete Unit with Additional Protection Plans for Major Parts

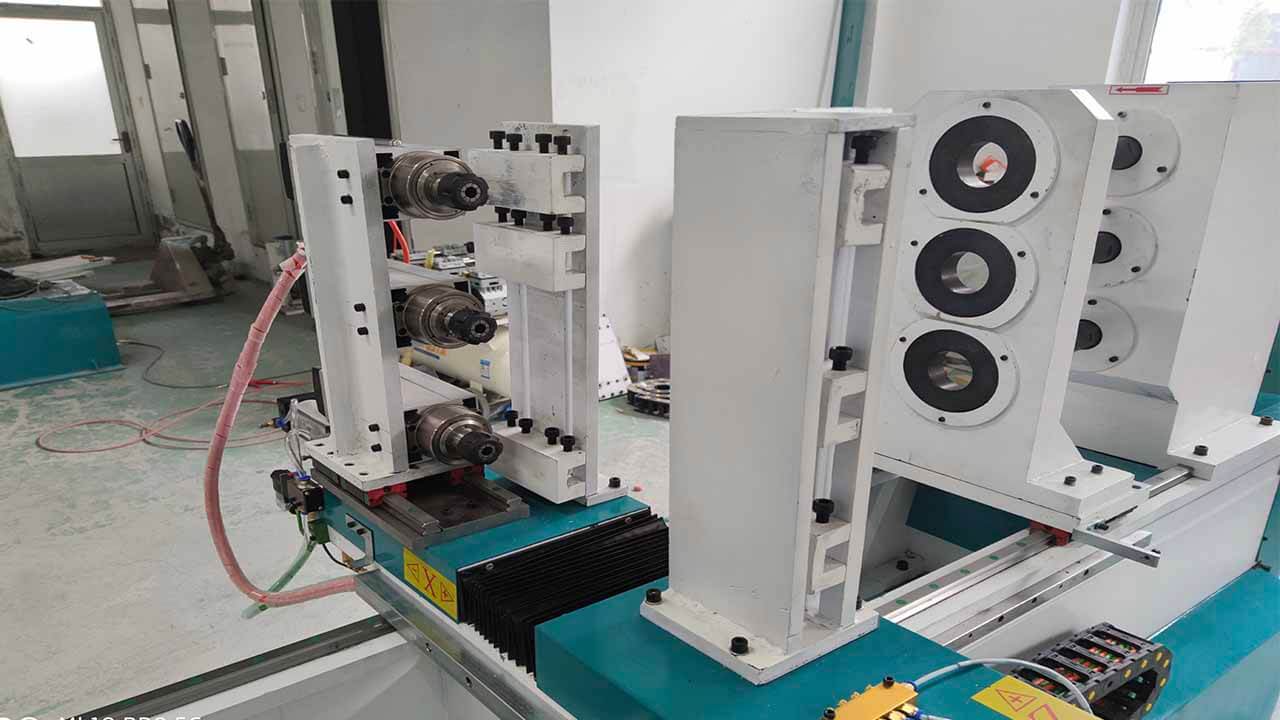

Overview of CT-1512 3 Axis Automatic Wood Turning Cnc Wood Lathe Machine

The 3-Axis Automatic CNC Wood Lathe Machine is a high-precision wood turning solution designed for fast, efficient, and smooth processing of wooden parts such as furniture legs, stair spindles, rolling pins, decorative posts, and craft products. Built with a heavy-duty cast iron structure and equipped with Taiwan TBI ball screws and Hiwin square guide rails, it ensures excellent stability, accuracy, and long service life. The dual-cutter system increases productivity and improves surface finish quality. Featuring a powerful stepper motor, user-friendly LCD/DSP control, and USB file transfer compatible with AutoCAD and .dxf designs, this CNC woodworking lathe is ideal for professional furniture manufacturing, woodworking workshops, and wood craft production, delivering reliable performance for cylindrical, conical, curved, and custom wood turning jobs.

Key Features of CT-1512 3 Axis Automatic Wood Turning Cnc Wood Lathe Machine

- Flexible Processing Size

The 3-axis CNC lathe supports a maximum turning length of 1500mm and a standard turning diameter of 120mm. For larger workpieces, single-piece turning can reach 300mm diameter with optional lengths of 1500mm, 2000mm, or 2500mm. - Heavy-Duty Cast Iron Structure

The entire machine base is manufactured from solid cast iron and treated through high-temperature annealing and vibration stress relief, ensuring excellent rigidity, long-term stability, and zero deformation. - High-Precision Transmission System

Equipped with Taiwan TBI ball screws and Hiwin linear square guide rails, the lathe ensures smooth movement, high machining accuracy, and long service life. - Powerful Drive Performance

The machine uses a high-torque stepper motor paired with a Yako driver, ensuring fast and stable wood turning for both small details and long production runs. - Dual-Cutter Design for High Efficiency

Featuring two cutting tools positioned on opposite sides — roughing and finishing cutters work together through staged cutting, significantly boosting productivity while delivering a finer, smoother surface finish. - User-Friendly Operation with CAD Support

Compatible with CAD design software, allowing users to directly transfer .DXF files via USB for quick and easy programming and operation. - Smart LCD/DSP Control System

The handheld controller with USB interface allows simple tool alignment and setup, making design adjustments easier than operating through a computer. Perfect for on-site rapid configuration.

Specification of CT-1512 3 Axis Automatic Wood Turning Cnc Wood Lathe Machine

| Parameter | Details |

|---|---|

| Maximum Processing Size | 1500 mm length × 120 mm diameter × 3 workpieces (single piece up to 300 mm diameter) |

| Machine Base | Heavy-duty one-piece cast lathe with integrated frame and standalone control cabinet |

| Main Motor | 7.5 kW three-phase asynchronous motor |

| Drive System | Servo-driven with high-performance frequency inverter |

| Spindle Speed Range | 0–6000 RPM |

| Transmission Method | XY axis powered by 25 TBI ball screws; Z axis driven by high-precision helical rack and TBI 32 ball screw |

| Guide Rails | Taiwan Hiwin 25 mm linear square rails with 25 mm sliders on X, Y, Z axes |

| Cabling | Full copper wiring for reliable electrical performance |

| Electrical Components | Schneider / Delixi brand components for stable operation |

| Control Interface | Dedicated CNC control panel (CT1000TC) |

| Lubrication System | Manual oil fill and maintenance lubrication system |

| Power Supply | AC 380V / 220V, 50/60 Hz |

| Software Compatibility | Supports ArtCAM, Type3, AutoCAD, CorelDRAW, SolidWorks, UG, PowerMill, and similar programs |

| Programming / Engraving Format | Standard G-code, U00, MMG, PLT |

| Safety Features | Photoelectric limit switches installed on X, Y, Z axes for safe operation |

| Positioning Accuracy & Repeatability | ±0.02 mm |

| Included Accessories | Complete toolbox including turning tools, wrenches, handwheels, thimbles, chucks, oil bottles, oil-water separators, relays, and photoelectric limit devices |

Applications of CT-1512 3 Axis Automatic Wood Turning Cnc Wood Lathe Machine

The CT-1512 CNC wood turning machine is widely used for producing various cylindrical and artistic wooden components. It is designed for manufacturing furniture legs, stair spindles, rolling pins, table and chair legs, decorative wooden posts, vases, and round wood crafts with high precision. This 3-axis wood lathe supports processing of cylindrical, conical, spherical, and curved shapes, making it suitable for both mass production and custom woodworking projects. It is an ideal machine for furniture factories, staircase manufacturers, home decoration companies, and wooden handicraft workshops, providing efficient and accurate machining for a wide range of wooden products using materials such as oak, beech, ash, birch, teak, rosewood, and other hardwoods and softwoods.

Showcase of CT-1512 3 Axis Automatic Wood Turning Cnc Wood Lathe Machine

Ready to Upgrade Your Wood Turning?

Get your customized CNC wood lathe solution today. Contact us for detailed pricing and technical consultation