家具脚用補助給餌CNC木工旋盤

$7500-$9800

- モデル: CT-1530

- 作業サイズ:直径120~300mm、長さ1500mm

- カテゴリー: 3軸CNC木工旋盤

- エンドクライアントとディーラーの両方に対する継続的な技術指導

- 柔軟な支払い方法 - オンラインとオフラインでの安全な支払い - PayPal、Alibaba、T/T、カードが利用可能

- 国際輸送ネットワークでどこへでも時間通りの配送を実現

- ユニット全体に対する包括的な1年間の保証と主要部品に対する追加の保護プラン

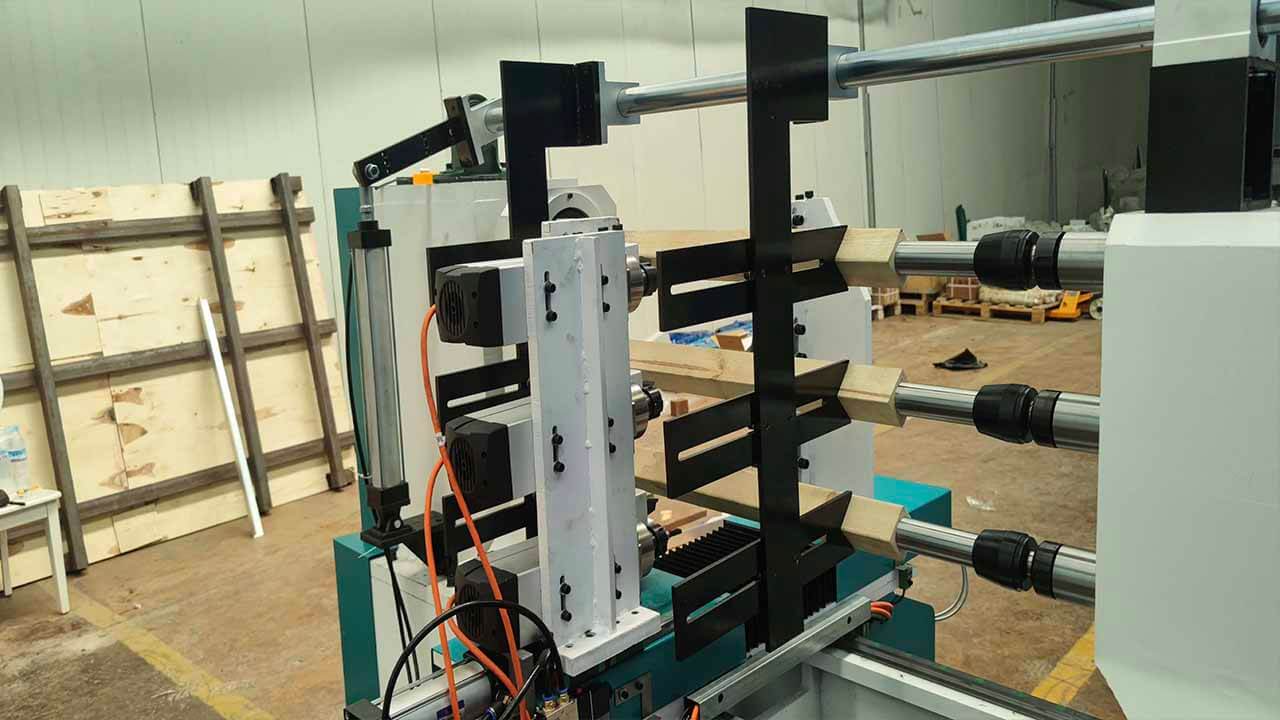

家具脚用補助給餌CNC木工旋盤の製品概要

その 家具脚用補助給餌CNC木工旋盤 家具の脚、階段の手すり、テーブルの柱、ベッドの支柱など、円筒形のワークピースの自動旋削・成形用に設計された高精度・高効率の機械です。頑丈な鋳鉄構造と高度なDSP制御システムを備え、安定性、操作性、信頼性の高い性能を実現します。補助送り機構により連続加工が可能になり、手作業の負担を軽減し、生産性を向上させます。 台湾Hiwinリニアガイドレール, TBIボールねじトランスミッション、そして 周波数変換スピンドルスムーズな回転、正確な切断、優れた表面仕上げを実現します。 ArtCAM、Type3、Ucancam、その他の設計ソフトウェアとUSBファイル転送をサポートし、柔軟で効率的な加工を実現します。このCNC木工旋盤は、 家具メーカー、木工工場、装飾工芸工房 精度、自動化、長期耐久性を追求しています。

家具脚用補助給餌CNC木工旋盤の主な特徴

- 高度なDSP制御システム: 使いやすい DSP ハンドヘルド コントローラを搭載しており、操作がシンプルで効率的、かつ習得も容易で、CNC 木工旋盤の初心者やプロに最適です。

- 強化スチールフレーム: 長さ 2.9 メートルの厚い溶接鋼ベースを採用し、高速加工時に優れた安定性、最小限の振動、長期耐久性を実現します。

- 可変速度制御: インバータベースの周波数速度調整システムを備えており、柔軟なスピンドル速度制御が可能で、木材のばたつきを防ぎ、スムーズな回転性能を保証します。

- 精密モーションコンポーネント: 活用 台湾Hiwinリニアスクエアガイドレール、ヘリカルラック、TBI ボールねじトランスミッションにより、高精度、安定した動作、長寿命を実現します。

- 強力なステッピングモータードライブ: 高トルクステッピングモーターと Yako 2811 ドライバーを搭載し、複雑な木材デザインでも信頼性の高いモーションコントロールと正確な処理を実現します。

- デュアルカット機能: 粗加工ツールと仕上げツールの両方をサポートし、表面品質の向上、サイクル時間の短縮、大量木工における生産効率の向上を実現します。

- 中央ポイント固定装置: ワークをしっかりと保持する中央位置決めシステムを装備し、加工精度を向上させ、旋削中に完全な対称性を保証します。

- ソフトウェアの互換性: 人気のデザインおよび彫刻ソフトウェアと完全に互換性があります。 ArtCAM、Type3、Ucancam、JDpaintUSB インターフェース経由で簡単にファイルを転送したり、パターンをカスタマイズしたりできます。

家具脚用補助給餌CNC木工旋盤の仕様

| アイテム | 詳細 |

|---|---|

| 機械フレーム | 安定性と耐振動性を実現する高強度鋳鉄構造 |

| 最大旋回直径 | 120~300mm(カスタムオプションは最大400mmまで利用可能) |

| 最大旋回長さ | 1500mm(オプションの延長モデルは最大2000mm) |

| スピンドル速度 | 調整可能な0~3000 rpmの高速回転スピンドル |

| 駆動システム | 精密制御のためのYako 2811ドライバと組み合わせたステッピングモーターモデル450C/450B |

| ガイドレール | スムーズで正確な動きを実現する25mm台湾HIWINリニアスクエアガイドウェイ |

| 伝送方法 | 安定した送り性能を実現する台湾TBI精密ボールねじ搭載のラック&ピニオン |

| 作動空気圧 | 0.6~0.8MPa |

| CNCコントローラー | 信頼性の高いパフォーマンスを実現する高度なDSP制御システム |

| 互換性のあるソフトウェア | Type3、ArtCAM、Artcut、Ucancam、JDpaintなどのデザインソフトウェアをサポート |

| プログラミング言語 | 標準Gコード形式 |

| コンピュータ接続 | 迅速かつ簡単なファイル転送を実現するUSBデータインターフェース |

| 動作電圧 | AC 380V、50/60Hz |

| 潤滑システム | 集中オイル潤滑によりメンテナンスが容易になり、長寿命化を実現 |

| 職場環境 | 温度: 0~45℃; 湿度: 30~75%RH |

| 機械寸法 | 2000 × 1300 × 1350 mm |

| 正味重量 | 安定した加工を実現する1600kgの高耐荷重設計 |

家具の脚のための補助給餌CNC木工旋盤の用途

補助給餌機能付きCNC木工旋盤は、様々な加工に広く使用されています。 円筒形の芸術的な木製品 のような ボウル、チューブ、装飾工芸品生産に最適です 階段の手すり、柱、階段の柱、テーブルの脚、椅子の脚、ソファの脚、バースツールの脚 一貫した精度で加工できます。この機械は旋削加工にも最適です。 ローマの柱、洗面台、木製の花瓶、ベッドの支柱、椅子の担架、手すり、パンの脚、ランプスタンド、野球のバット. 適しています 家具製造、室内装飾、木工品製造このCNC木工旋盤は、高品質の仕上げを実現します。 曲線、円錐、球形、円筒形の木材部品 オーク、アッシュ、バーチ、チーク、ローズウッドなどの材料で作られています。

家具脚用補助給餌CNC木工旋盤の製品展示